A virtual factory is a computer-generated simulation of a manufacturing facility that allows designers, engineers, and other stakeholders to visualize and optimize the production process before actual production begins. It is a digital twin of a real-world factory that allows for testing and experimentation without the need for physical resources.

The virtual factory is typically created using advanced 3D modeling and simulation software such as CATIA, which allows for the creation of detailed and accurate 3D models of the factory layout, equipment, and processes. The software can also simulate the movement of materials, the behavior of machines, and the interactions between different elements of the factory.

The virtual factory allows for the optimization of production processes by allowing designers and engineers to test and refine different scenarios and configurations. This can lead to improvements in efficiency, productivity, and quality, while also reducing costs and risks associated with physical testing and experimentation.

Additionally, the virtual factory can be used for training and education purposes, allowing new employees to familiarize themselves with the factory layout, equipment, and processes before they start working on the actual factory floor.

Overall, a virtual factory is a powerful tool for optimizing production processes, reducing costs and risks, and improving the efficiency and productivity of manufacturing facilities.

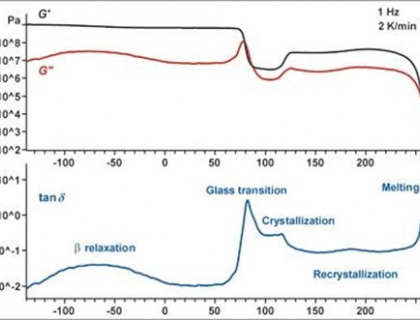

Mechanical analyses refer to the study and characterization of the physical properties of materials or systems under mechanical stress, deformation or loading.

Read moreMechanical analyses refer to the testing or analysis of the mechanical properties and behavior of materials or structures under applied stress, deformation, or load.

Read more

Virtual reality (VR) is a technology that allows users to experience a computer-generated 3D environment as if they were present within it. In the context of design offices, VR can be used to enhance the design process by providing designers with an immersive, interactive, and collaborative environment in which to view and evaluate their designs.

Read more